Medtec is a specialised exhibition dedicated to medical equipment R&D and manufacture. We not only commit to meeting the needs of R&D sector for high-performance materials, precision components, chokepoint chip elements, and advanced design software, but also addresses diverse requirements of the manufacturing end for production equipment, processing technologies, and services.

Freely explore each exhibitor’s offerings to uncover unique solutions tailored for your company. September 1-3, 2026, SNIEC N1-N4: A Premier Gathering for Medical Device Manufacturing and R&D.

Unlike exhibitions showcasing finished medical devices, Medtec primarily caters to engineers, decision-makers, and influencers from R&D, engineering, design, procurement, process, management, quality, and regulatory departments. It provides a platform for the exchange of diverse ideas and solutions.

Global Medical Tubing Market To Grow At A CAGR of 5.5% By 2030

Addressing the Rising Price & Demand of Nitinol

- 2026 Medtec

- ADTE

- Quality Expo

– Metallic Raw Materials and Components

– Advanced Ceramic, Biological, and Glass Materials and Related Components

– Super-Precision Laser Processing, Machine Tools and Additive Manufacturing

– ADTE High-End Active Medical Equipment Technology Exhibition

– Medical Raw Materials (Ploymer/ Composite Materials) and Components

– Adhesives and Bonding Products

– Medical Tubing and Extrusion Products

– IVD Reagents, Filtration, Intravenous Injection, and Laboratories

– Pharmaceutical Delivery Systems, Dressing Materials and Formulation Processing

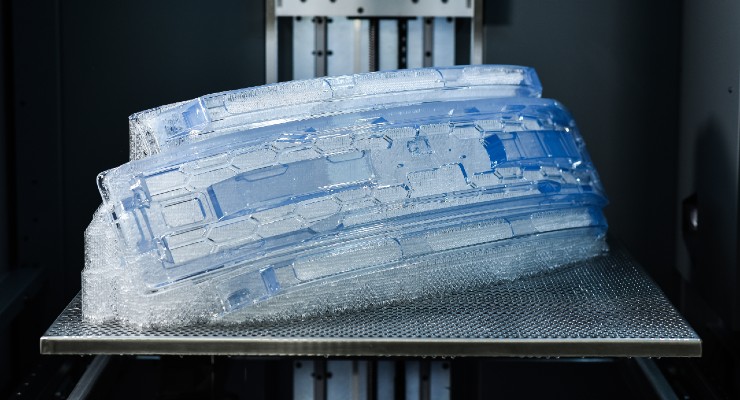

– Molding Services and Equipment

– Tubing and Extrusion Equipment

– Surface Treatment

– OEM/ODM Full-Service Contract Manufacturing

– Medical Integration & Automation, Drive Control, Robotics, and Smart Factory Solutions

– Medical Packaging, Sterilization, Labeling, and Cleanroom Technologies

– R&D Design, Software Services, Consulting

– Testing, Metrology, Inspection, and Supplies Exhibition

· 芯片传感

· 集成电路

· 连接器线束

· 电源电机

· 软件配套

· AI

· 5G智慧医疗

· 影像设备核心组件

· 光学组件

·内窥镜部件

· 激光器

· 成像解决方案

· 测试

· 计量

· 检验

· 校准设备及用品

In concurrent with Medtec, this event focuses on the full lifecycle of medical device R&D, design, manufacturing, and commercialization, it fosters collaboration and innovation across the supply chain. Simultaneously, we will delve into the development trajectories of innovative medical devices and active medical devices, explore the challenges and opportunities encountered by medical device companies in their global expansion, and assist enterprises in achieving new breakthroughs.

This summit will run concurrently at the exhibition venue for three days.

- Exhibition News

- Company News

- Industry News

- R&D Consulting

- Industry Insights

- Investment & M&A

- Regulations & Quality

Read More

Read More

Read More

Read More

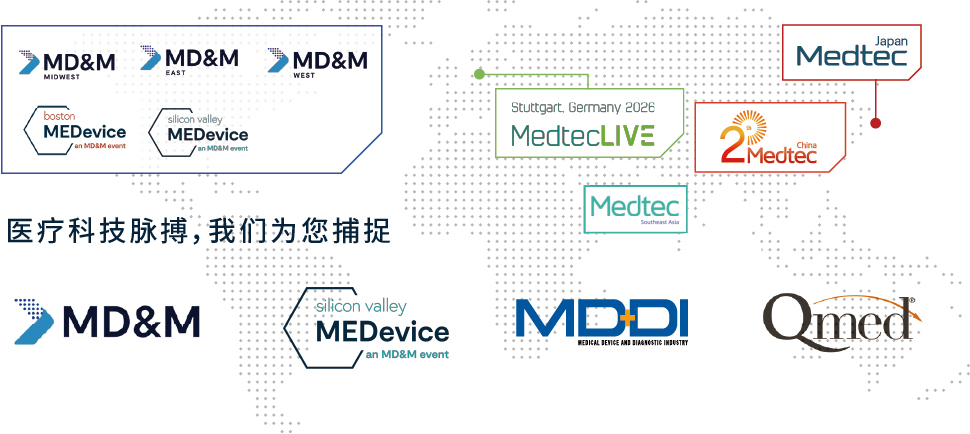

· Medtec China 2026.9.1-3

· Medtec Japan 2026.4.21-23

· Medtec Southeast Asia 2026.7.8-10

· MD&M Mideast 2026.10.28-29

· MD&M WEST 2026.2.3-5

· MD&M EAST 2027.5.19-20

· MEDevice Silicon Valley 2025.11.19-20

· MEDevice Boston 2026.8.26-28

· MedtecLIVE 2026.5.5-7

*For the exact dates of the above exhibitions, please always refer to their official websites for final confirmation.