Nitinol grips prevent slips in Abbott’s heart valve clips

Nitinol is a key material in the heart valve clips that Abbott designed for its TriClip and MitraClip transcatheter edge-to-edge repair (TEER) systems.

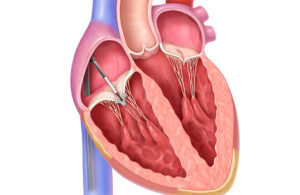

Abbott designed the TriClip system (approved by the FDA in April 2024) for reducing tricuspid valve regurgitation using fourth-generation heart valve clips that Abbott originally developed for the MitraClip transcatheter mitral valve repair (TMVr) system more than a decade ago.

Abbott turned to nitinol as a crucial design change from the first generation of that clip to improve its grip on the heart valve’s thin, flexible leaflets, said Santosh Prabhu, divisional VP of product development for Abbott’s structural heart business.

Nitinol frictional elements are an essential component of the heart clip’s grippers, he explained in an interview with Medical Design & Outsourcing.

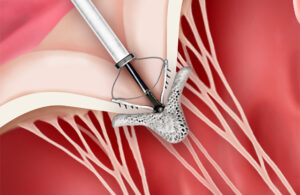

“Grippers, as the name suggests, are used for gripping the leaflets,” he said. “Those grippers have these elements called frictional elements. These are tiny protrusions on the grippers that engage with the leaflets and prevent them from slipping out. You insert the leaflets between the clip arms and the grippers and you drop the grippers. Now the grippers have gripped onto the onto the leaflets and then you close the clip arms. You have the leaflets well engaged and they won’t come out.”

This illustration shows the catheter-delivered TriClip implantation in the tricuspid valve. [Image courtesy of Abbott]

Rows of frictional elements along both grippers of the clip’s arms secure the leaflets without perforating them.

Abbott made the first-generation frictional elements out of Elgiloy, a brand of super-alloy consisting mostly of cobalt, chromium and nickel, with lesser amounts of molybdenum, manganese, silicon, carbon, beryllium, phosphorus, sulfur and iron.

But that alloy lacked an important property that has made nitinol (a nearly equiatomic alloy of nickel and titanium) so popular among medical device developers, Prabhu said.

Elgiloy “was not superelastic, and therefore it wouldn’t drop all the way down,” he said. “But that was one of the major changes that we made when we came up with the second-generation clip, which is the MitraClip NT. The TriClip product is derived from the MitraClip product — all versions of the TriClip product have had the nitinol grippers.”

The clips themselves are made of cobalt-chromium and covered with polyester, a design meant to promote tissue growth and prevent thrombus formation.

“Cobalt-chromium has very good strength for our applications, and at the same time is radiopaque, so it’s easier to visualize under fluoroscopy. It’s also very pliable for a metal, so you can shape it into different forms. The clip arms of the MitraClip are made of Elgiloy,” he said. “Nitinol, on the other hand, is used more for shape-memory or superelastic effects. It doesn’t undergo plastic deformation very easily. That’s where it lent itself in designing the grippers, because you have to close and open the clip arms multiple times during a procedure sometimes. Both during manufacturing and during the use of the product, you have to open and close the clip arms. Now the grippers have to open and close along with it, and you can’t afford to have it undergo plastic deformation because then it won’t go back to its original shape and drop down and engage with the leaflets. And that’s where nitinol came in.”

This close-up of the illustration above shows the frictional elements on the clip’s grippers securing the tricuspid valve’s leaflets. [Image courtesy of Abbott]

Another important nitinol component is the leaf spring, which helps lock and unlock the clip.

“Again, it has to regain its original shape, and when you either lock the clip or unlock the clip, it has to deform and not undergo plastic deformation,” Prabhu said.

So why didn’t Abbott use nitinol for the gripper frictional elements to begin with? Their sharp configurations just couldn’t be manufactured with nitinol at the time, he said.

“Ten years later, laser technology was available to make some of those changes. [For] a lot of the things that we think we cannot do now, the technology might evolve,” Prahbu said.

Santosh Prabhu is divisional VP of product development for Abbott’s structural heart business. [Photo courtesy of Abbott]