New Report Expects AI to Drive Revenue Management Value in 2025

Model N’s 2025 State of Revenue Report reveals shifts toward the use of generative AI and automation to bolster medtech and high-tech revenue programs.

Packaging for Med Device Companies: EO and CD Considerations

What medical device manufacturers should keep in mind when packaging for chlorine dioxide (CD) versus ethylene oxide (EO).

BD Increases US Syringe Production After FDA Warnings on China-Made Syringes

Becton, Dickinson and Company (BD) has announced its intention to increase US production of syringes after FDA recently reported that its ongoing investigation into quality issues with plastic syringes made in China were “more widespread” than originally known.

Medtronic Muses on Diabetes Management Technologies

MPO recently spoke to Ali Dianaty, SVP of product innov […]

3 surprising cybersecurity risks in medical device software

Healthcare cybersecurity conversations typically focus on hospital IT networks and patient data protection. What’s less talked about is the risks in the software powering medical devices themselves.

Is Digital Health Evolving Too Quickly?

Digital health is evolving in leaps and bounds, which could be threatening its success. Digital healthcare faces a significant challenge: it is evolving too rapidly for its target market. Health systems struggle to develop new workflows that effectively integrate these technologies, and trying to force them into legacy processes often adds more problems to an overburdened system.

The Extravascular Implantable Cardioverter-Defibrillator: A Promising Novel Device

Transvenous implantable cardioverter-defibrillators (ICDs) are the reference standard for preventing sudden cardiac death (SCD) but have risks associated with intravascular lead placement.1 ICD technology has evolved from the epicardial to the transvenous era to extravascular innovations that avoid vascular complications, including cardiac perforation, venous obstruction, increased infection rates, and tricuspid regurgitation.

Smart Implants: Revolutionizing Healthcare with Cutting-Edge Technology

In recent years, the medical field has seen a wave of innovation with the advent of smart implants. But what exactly are these advanced devices, and how do they work?

Managing Miniaturization: Thermal Protection Is Critical at Any Size

Medical devices have been around for centuries. Egyptians designed bronze scalpels and lancets almost 5,000 years ago, but today, pacemakers, artificial joints, and 3D-printed implants are the norm, and far more compact and complex.

Designing Medical Devices with Intelligence

The medical device industry is experiencing rapid advancements in product design and prototyping as a result of new or improved manufacturing technologies. For example, “additive manufacturing has evolved from a novelty to a robust and mature method, enabling designers and product developers to create complex prototypes quickly and efficiently,” said Jim MacDonald, business development manager for Vaupell, a Constantine, Mich.-based contract manufacturer that provides engineering, design, and manufacturing services to the medical device industry.

Avoid these four common blunders when using nitinol for medical devices

Nitinol’s unique properties make it ideal for many medical device innovations.

It can return to a predetermined shape when heated above a certain temperature, which is useful for applications requiring precise actuation and control, including medical stents and actuators.

Enhancing Manufacturing Efficiency with High-Performance Coatings

Medical device manufacturing is a highly regulated industry that demands precision and faces numerous challenges. Ensuring efficiency, compliance, and safety is crucial for maintaining the integrity of the manufacturing process and the quality of the final products.

Guest Editorial: The Power of One When Choosing Stent and Catheter Partners

As device designs become increasingly sophisticated, medtech companies are understandably seeking contract design and manufacturing partners that can accompany them on comprehensive product journeys — from initial concept to validation to large-scale manufacturing, and everything in between. This places a differentiating premium on partners with the ability to combine ideation and early-stage development with materials science and process technologies.

Proof of Life: The Rapid Evolution of Biosensors for Fitness, Health, and Wellness

Biosensors are devices that can monitor physiological states, like heart rate or blood pressure, or detect biological parameters such as glucose levels or the presence of specific proteins in the blood.

4 Ways Ultrafast Laser Techniques Reshape the Medical Manufacturing Landscape

Medical device manufacturing has significantly advanced over the past several decades, resulting in more innovations for producers, providers, and patients. Ultrafast lasers are important for allowing companies to create more cutting-edge items in shorter time frames.

When Models Fail: Bridging the Gap Between Analytical Models and Empirical Data

Neither analytical models nor physical experiments are sufficient on their own. Progress comes from their interplay, each informing and helping to refine the other. We can resolve discrepancies and deepen our understanding of complex systems by embracing an iterative, informed, systematic approach. And get on with the job of designing and developing the medical device that fills needs and improves lives.

Transformative Medical Device Testing

The medical device industry is on the brink of profound transformation, driven by breakthroughs in artificial intelligence (AI), wearables, additive manufacturing (AM), and enhanced cybersecurity. Medical device manufacturers (MDMs) are starting to embrace the integration of automation, digitization, and Internet of Things (IoT) technologies. So far in 2025, testing firms report increased interest in the end-of-life use of reusable devices, human factors testing for instructions for use (IFU), and low-temperature sterilization methods for temperature-sensitive devices.

Incorporating Medical Device Risk Management into QMS Protocol

How to improve current risk management processes, ensur […]

The Critical Role of Supply Chain Visibility for Post-Market Surveillance

In recent years, medical device regulators have implemented stricter requirements for post market surveillance (PMS), as seen in frameworks like the EU Medical Device Regulation (MDR), the In Vitro Diagnostics Regulation (IVDR), and the UK’s Statutory Instrument (SI) coming into effect on June 16, 2025.

How Early FDA Engagement Can Accelerate Medical Device Approval & Reduce Market Delays

By interacting with FDA as early as medical device conception, and taking advantage of one or more FDA programs, manufacturers can shorten their time to market and significantly reduce expenditures.

Will Abbott Have a Strong Year for M&A?

During a 4Q23 earnings call, Ford was asked by an analyst about Abbott’s strong balance sheet, which was described as “$20 billion worth of firepower”, and if that would prompt the company to become involved with acquisitions this year.

MMT Acquires Ward Automation Galway, Somex: Launches MMT Automation Division

The addition of these technologies and services enables MMT to better serve its medical device manufacturing customers by offering highly specialized robotization and integrated solutions for their most challenging production needs.

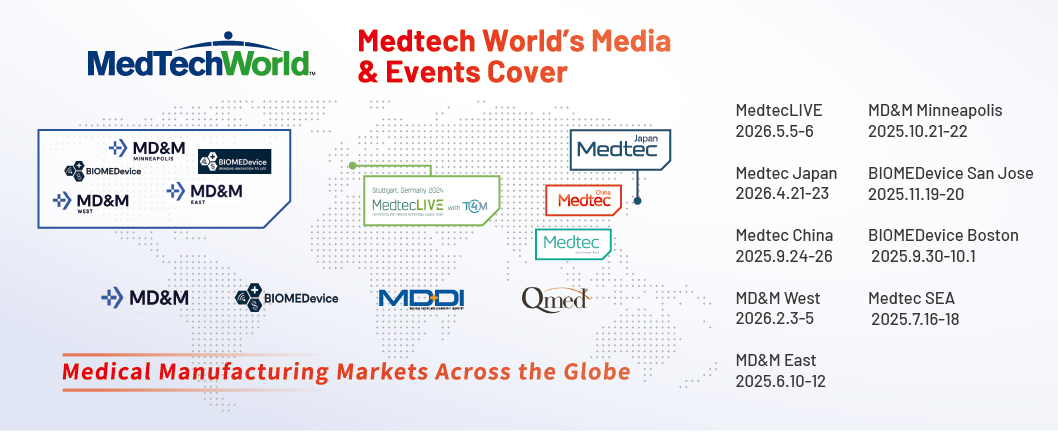

Join in MedTech World, and communicate with more than 2000 global advanced suppliers.

Media Partner