New Report Expects AI to Drive Revenue Management Value in 2025

Model N’s 2025 State of Revenue Report reveals shifts toward the use of generative AI and automation to bolster medtech and high-tech revenue programs.

Packaging for Med Device Companies: EO and CD Considerations

What medical device manufacturers should keep in mind when packaging for chlorine dioxide (CD) versus ethylene oxide (EO).

BD Increases US Syringe Production After FDA Warnings on China-Made Syringes

Becton, Dickinson and Company (BD) has announced its intention to increase US production of syringes after FDA recently reported that its ongoing investigation into quality issues with plastic syringes made in China were “more widespread” than originally known.

Medtronic Muses on Diabetes Management Technologies

MPO recently spoke to Ali Dianaty, SVP of product innov […]

Is Digital Health Evolving Too Quickly?

Digital health is evolving in leaps and bounds, which could be threatening its success. Digital healthcare faces a significant challenge: it is evolving too rapidly for its target market. Health systems struggle to develop new workflows that effectively integrate these technologies, and trying to force them into legacy processes often adds more problems to an overburdened system.

Four Bold Predictions for Medtech in 2025: AI Everywhere, Faster Releases, and Rising Risks

Four promising trends that medtech companies should be aware of heading into 2025 to stay ahead of competition.

3D Ink Improves Comfort, Durability of ‘Smart Wearables’

Researchers have demonstrated a 3D ink printing method for so-called smart fabrics that continues to perform well after repeated washings and abrasion tests. The research represents a breakthrough in smart fabric comfort and durability, as well as using a process that is more environmentally friendly.

AI-assisted Model Enhances MRI Heart Scans

An AI-assisted model developed by researchers from the University of Missouri School of Medicine and the School of Engineering can take low-quality MRI heart scans and turn them into high quality images, while reducing the time needed to scan the heart by about 90%.

Managing Miniaturization: Thermal Protection Is Critical at Any Size

Medical devices have been around for centuries. Egyptians designed bronze scalpels and lancets almost 5,000 years ago, but today, pacemakers, artificial joints, and 3D-printed implants are the norm, and far more compact and complex.

Designing Medical Devices with Intelligence

The medical device industry is experiencing rapid advancements in product design and prototyping as a result of new or improved manufacturing technologies. For example, “additive manufacturing has evolved from a novelty to a robust and mature method, enabling designers and product developers to create complex prototypes quickly and efficiently,” said Jim MacDonald, business development manager for Vaupell, a Constantine, Mich.-based contract manufacturer that provides engineering, design, and manufacturing services to the medical device industry.

Wound Dressings Made of Drug-Releasing Polymers

Electrospinning has been used to produce polymer fibers containing the well-known antibacterial drug metronidazole. The mats formed could potentially be used as wound dressings, thanks to an appropriately selected polymeric structure capable of releasing the drug into the body in a controlled manner.

Enhancing Manufacturing Efficiency with High-Performance Coatings

Medical device manufacturing is a highly regulated industry that demands precision and faces numerous challenges. Ensuring efficiency, compliance, and safety is crucial for maintaining the integrity of the manufacturing process and the quality of the final products.

Guest Editorial: The Power of One When Choosing Stent and Catheter Partners

As device designs become increasingly sophisticated, medtech companies are understandably seeking contract design and manufacturing partners that can accompany them on comprehensive product journeys — from initial concept to validation to large-scale manufacturing, and everything in between. This places a differentiating premium on partners with the ability to combine ideation and early-stage development with materials science and process technologies.

Proof of Life: The Rapid Evolution of Biosensors for Fitness, Health, and Wellness

Biosensors are devices that can monitor physiological states, like heart rate or blood pressure, or detect biological parameters such as glucose levels or the presence of specific proteins in the blood.

A pacemaker is a small device that helps control your heartbeat so you can return to your normal life. It has three main parts: a pulse generator that creates electrical signals, a controller-monitor that manages these signals, and leads that deliver the signals to the heart. One key benefit of the pacemaker is its strong titanium casing. Titanium is very strong and lightweight, and it is biocompatible, meaning it works well with the body without causing harmful reactions. This metal is highly resistant to corrosion, which helps keep the casing intact and protective even when exposed to bodily fluids.

Enhancing Manufacturing Efficiency with High-Performance Coatings

Medical device manufacturing is a highly regulated industry that demands precision and faces numerous challenges. Ensuring efficiency, compliance, and safety is crucial for maintaining the integrity of the manufacturing process and the quality of the final products. Adherence to FDA regulations and Current Good Manufacturing Practice (cGMP) standards requires manufacturing facilities to uphold clean and controlled environments, often resulting in considerable downtime and maintenance expenses. These shutdowns can disrupt production schedules, impact productivity, and ultimately affect profitability.

Your Guide to Medical Device Sterilization: Methods, Compliance, Challenges & Trends

Sterilization has always played a central role in medical device development. But today, it’s no longer just a matter of checking a regulatory box or signing off on a quality assurance protocol. It’s a design constraint, a supply chain risk, and increasingly, a competitive differentiator. Further, a next generation of sterilization modalities are emerging.

Transformative Medical Device Testing

The medical device industry is on the brink of profound transformation, driven by breakthroughs in artificial intelligence (AI), wearables, additive manufacturing (AM), and enhanced cybersecurity. Medical device manufacturers (MDMs) are starting to embrace the integration of automation, digitization, and Internet of Things (IoT) technologies. So far in 2025, testing firms report increased interest in the end-of-life use of reusable devices, human factors testing for instructions for use (IFU), and low-temperature sterilization methods for temperature-sensitive devices.

Test and Measurement: Regulatory Updates and Strategic Implications

Medical device companies are operating in a climate of rapid transformation. The traditional regulatory and testing frameworks that have guided development for decades are evolving, prompted by technological innovation, increased globalization, and lessons learned during recent public health challenges.

The Critical Role of Supply Chain Visibility for Post-Market Surveillance

In recent years, medical device regulators have implemented stricter requirements for post market surveillance (PMS), as seen in frameworks like the EU Medical Device Regulation (MDR), the In Vitro Diagnostics Regulation (IVDR), and the UK’s Statutory Instrument (SI) coming into effect on June 16, 2025.

Will Abbott Have a Strong Year for M&A?

During a 4Q23 earnings call, Ford was asked by an analyst about Abbott’s strong balance sheet, which was described as “$20 billion worth of firepower”, and if that would prompt the company to become involved with acquisitions this year.

MMT Acquires Ward Automation Galway, Somex: Launches MMT Automation Division

The addition of these technologies and services enables MMT to better serve its medical device manufacturing customers by offering highly specialized robotization and integrated solutions for their most challenging production needs.

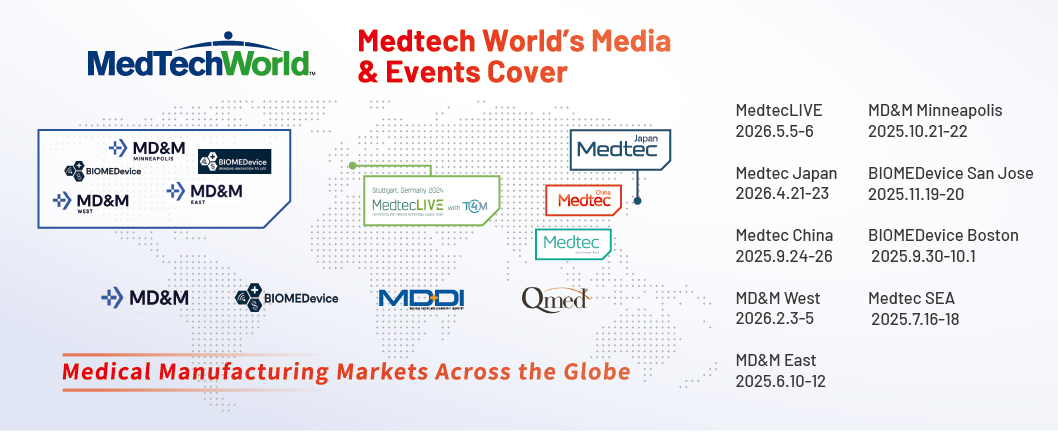

Join in MedTech World, and communicate with more than 2000 global advanced suppliers.

Media Partner