Medical Device Design Decisions: Choosing Between Disposable & Reusable

Successful new medical devices hinge on the designer’s understanding of the specific requirements of the procedures they support, including factors like usage frequency and duration. This is particularly critical early in the development process when deciding whether to create a device that is disposable or reusable. Each type of device has its own set of advantages and challenges. As sustainability becomes increasingly important, evaluating whether a device should be disposable or reusable involves not only technical and economic considerations but also an assessment of environmental impact. This article explores the key criteria for evaluating disposable versus reusable designs and providing insights to guide engineers in making informed decisions.

Criteria for evaluating disposable versus reusable devices

In order to decide whether a disposabl or reusable device best meets the needs of patients, medical professionals, and the overall system, considerations must include patient outcome and procedure efficiency, cost and complexity, procedure setting, sterilization considerations, and material selection. Each factor influences the device’s effectiveness, economic viability, and sustainability. By carefully examining these aspects, engineers can ensure that their design not only performs optimally but also aligns with practical and environmental considerations.

Patient outcome and procedure efficiency: The ultimate goal for medical device design engineers is to deliver a successful outcome for the patient while also minimizing any discomfort for both the patient and the medical professional. When developing the device, the engineer translates the procedure requirements into a design that will accomplish the task in the most efficient manner. The device’s operating life is determined by the specific treatment or therapy it supports and the frequency of its use across the patient population. These considerations are crucial when making the initial decision on whether to pursue a disposable or reusable design.

Cost and complexity: The nature and cost of the procedure or treatment often dictate the appropriate device type. Basic procedures typically favor disposable devices due to their lower initial cost, while complex treatments requiring high precision and accuracy may call for reusable designs. Since medical device development is a lengthy process from initial concept through production qualification that can span several years, any changes to the design can delay the project by months or even years. Therefore, making an informed decision early on about whether to design a disposable or reusable device is important to the success of the project.

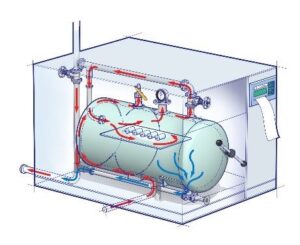

Autoclave equipment is essential, as the cost per sterilization cycle and the target number of cycles significantly impact the design and usability of various devices. Image courtesy of Portescap.

Sterilization: Various sterilization methods, such as autoclaving, require facilities to invest in specialized equipment to support the process. Once the investment is made, the cost per sterilization cycle becomes a significant factor in determining the device’s design. The target number of sterilization cycles will depend on the frequency and duration of the device’s usage. While aiming for a higher number of cycles can extend the device’s usability, it also increases design and production costs. For instance, the device may need to be sealed to protect internal components during sterilization, and the type of sealing method and materials direct both the cost and the number of achievable cycles.

The procedure’s setting: Hospitals usually have the necessary infrastructure for sterilization and can handle a larger volume of patients, making them better suited for reusable devices. In contrast, local offices may lack sterilization equipment and serve fewer patients, making disposable devices a more practical choice.

Material selection: Selecting the appropriate materials for the device components is critical, particularly for those that need to withstand repeated autoclave cycles. Higher-grade plastics or metals are required to provide the necessary durability, which in turn raises costs. For disposable devices, material choices are predicated on ensuring the device performs effectively for the duration of the procedure, with lower-grade materials often being sufficient. For reusable devices, the disposable components must be considered consumables for each procedure. This adds complexity to the evaluation process and requires input from various departments.

Sustainability: If the decision favors a disposable design, sustainability also becomes a key factor. Engineers must ensure that materials used in the device can be recycled without compromising the device’s performance. This consideration extends to the device’s electronics — more-complex electronics needed for advanced treatments often produce more waste. Packaging, which is discarded before each use, is another consideration. Maximizing the recyclability of all device components helps reduce medical waste and aligns with the growing trend towards sustainability.

Portescap’s range of Athlonix brush DC motors, Ultra EC BLDC motors, and stepper motors offer distinct advantages for diverse applications, balancing speed, precision, and cost-effectiveness. Images courtesy of Portescap.

Motor technology options for reusable and disposable devices

For medical devices that require a motion system, the choice of components largely depends on whether the design is disposable or reusable. Typically, standard components are used for disposable devices, provided they meet the necessary torque and speed requirements. Conversely, reusable devices require custom components to precisely match specific performance needs. The choice of motor technology will significantly impact the device’s overall design and performance.

Motor selection: Three primary motor technologies are available for medical devices: brushed DC, brushless DC (BLDC), and stepper motors. Each type has distinct advantages suited to different applications. For example, BLDC motors are ideal for applications requiring high speed and long operating life, while brushed DC motors excel in delivering medium speed and torque. Stepper motors are desirable where precision and cost-effectiveness are essential. For a disposable design that requires high speed, a BLDC motor can be a sound choice. However, if the device has a short operational duration, a brushed DC motor may be sufficient if testing can show that it performs well beyond its maximum speed specification of 10,000 rpm, even for a 15-minute operation.

Portescap’s B16C gearhead is an example of a gearing solution that can be mechanically customized for suit specific application needs. Image courtesy of Portescap.

Gear drives: Applications demanding higher torque and lower speeds are well-suited for gear drives. Standard gearboxes may be appropriate for disposable devices, given their typical rating for hundreds or thousands of operating hours. However, custom gear drives allow designers to select the best material to meet the minimal operating time requirements while maximizing performance. For reusable designs, customization allows designers to create the optimal form factor and select sterilizable materials based on the expected number of cycles.

Regarding cost, standard components are often assumed to be more cost-effective. However, this is not always the case. Custom systems can become more economical when a specific production volume threshold is met. Therefore, it pays to evaluate custom solutions during the concept phase of either design type in order to get the best value and performance.

Develop optimal disposable and reusable medical device designs

When choosing whether to design disposable or reusable medical devices, engineers must weigh a long list of factors ranging from motor and gearing technology to sterilization practices and material sustainability, as well as costs. Reviewing these factors early in the development process helps satisfy a design’s performance and economic requirements while also aligning with environmental goals.

Portescap, known for its advanced motion solutions, offers tailored support for both disposable and reusable designs. Engineers can leverage our extensive knowledge and experience to develop optimized devices that balance performance, cost-effectiveness, and environmental impact, ensuring the best outcomes for both patients and medical professionals.

For more information about Portescap motors for medical devices, visit www.portescap.com.

Case Study Sidebar: Drug Delivery Devices

The debate over disposable versus reusable designs is particularly relevant for drug delivery devices. Devices delivering post-operative drugs for recovery or pain management may be ideal candidates for disposable designs due to their limited use. In contrast, devices treating chronic conditions or enabling normal daily life are typically better suited for reusable designs, lowering the cost of ownership for the patient.

Author:Dave Beckstoffer