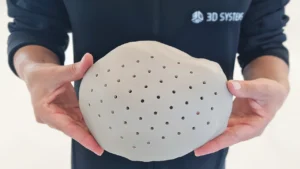

3D-printed PEEK-based Cranial Implants Cleared by FDA

3D Systems has received 510(k) clearance from the US Food and Drug Administration (FDA) for its 3D-printed, patient-specific cranial implant system. The VSP PEEK Cranial Implant includes a complete FDA-cleared workflow comprising segmentation and 3D modeling software, 3D Systems’ EXT 220 MED 3D printer, Evonik’s VestaKeep i4 3DF polyetheretherketone (PEEK) resin, and a pre-defined production process.

In addition to producing patient-specific cranial implants, the technology reportedly uses up to 85% less material than implants produced by traditional machining. That can have a significant impact on cost when using expensive raw materials such as implantable PEEK.

Designed for use in hospitals.

The 3D printer’s cleanroom-based architecture combined with simplified post-processing workflows makes it an ideal technology for producing patient-specific medical devices at the hospital site, according to 3D Systems.

Thus far, nearly 40 successful cranioplasty procedures have been performed in Switzerland, Austria, and Israel using this technology, and it has received a ringing endorsement from a neurosurgeon at the University Hospital in Salzburg, Austria.

“3D-printed PEEK cranial plates are an innovative solution that can improve patient care and expand the possibilities for precise, individualized neurosurgery,” said Dr. Johannes Pöppe, senior attending surgeon in the department of neurosurgery at the Austrian hospital. “The solution is revolutionizing the field. The combination of 3D Systems’ printing technology that is uniquely engineered for sterile environments along with the mechanical properties of PEEK are helping surgeons push boundaries.”

FDA clearance of the system — and it is reportedly the first additively manufactured PEEK implant for cranioplasty procedures to be cleared by the agency — will enable 3D Systems to significantly expand its PEEK product portfolio through the EXT 220 MED platform. It also sets the stage for a range of advanced PEEK-based products designed to meet the diverse needs of the medical field, added 3D Systems.

PEEK is uniquely suited for medical device applications.

PEEK polymer is especially well suited for medical device applications thanks to its biocompatibility, resistance to body fluids, and stability in a range of temperatures. The material’s inherent radiolucency ensures minimal interference in medical imaging. Its performance and mechanical properties that closely mirror those of human bone make PEEK an ideal material specifically for the cranial implant application, according to 3D Systems.

“With this FDA clearance, we are now able to bring VSP PEEK Cranial Implant to the United States, setting a new standard of excellence for these procedures,” said Dr. Gautam Gupta, SVP and general manager, medical devices, at 3D Systems. “We are now looking to the next applications for this technology, which include 3D-printed spine interbody fusion implants, carbon-fiber-reinforced PEEK for plating applications in trauma and fixation, and bioresorbable polymers for large bone and craniomaxillofacial applications,” added Gupta.

Size of cranial implants market will approach $2.1 billion by 2030.

Cranial implants can address a range of applications, including trauma, defects, and reconstruction, and the use of 3D-printed implants will accelerate based on the availability of advanced technologies, according to 3D Systems. A report from Acumen Research and Consulting in February 2023 pegged the cranial implants market size in 2021 at roughly $1.2 billion. It is anticipated to approach $2.1 billion by 2030.

Article Source: MDDI