Advancing Medtech Requires Advanced Battery Technology to Match

Fig. 1 – Ultrasonic welder, showing tooling (horn and anvil). (Credit: Emerson)

As medical devices in today’s modern medicine continue to advance, they require power supplies that allow them to perform an ever-widening roles. These lightweight, wearable — and even implantable — medical devices comprise everything from activity/exercise watches, hearing aids, and medical call buttons to pacemakers, insulin pump monitors, and neuro- or gastric stimulators, as well as implantable cardiac pacemakers and defibrillators (ICDs). The rechargeable batteries used in these devices must provide for such vital functions as monitoring, signal processing, collecting and transmitting data, and providing specialized electronic pulses when needed to stimulate cardiac output and other physiological activity.

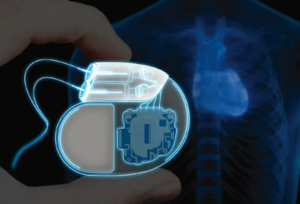

The rechargeable batteries or battery cells used in wearable and portable devices must be small and easy to replace and provide long-lasting power supply. Currently such devices are available in a variety of standard sizes as both cylindrical and button-type cells. However, unlike wearable and portable devices, implantable devices such as pacemakers and ICDs require batteries made to a more rigorous standard. These devices must not only be extremely compact but also be made of biocompatible materials and provide extremely long-lasting power, as replacing them is difficult (requiring minor surgery) or impossible.

These batteries not only must be long-lasting but also must fit into the overall contours of the wearable or implant itself. Some devices may accommodate cylindrical batteries, which consist of layers of electrode foils wrapped around a central core, surrounded by electrolyte, with tabs that link the anode (positive) and cathode (negative) foils to the respective battery terminals. The other main battery design is the button cell, a coin-like battery whose flat structure employs a single thin-foil anode and cathode (4-6 μm in thickness), with each bonded to one of the battery sides, or terminals.

Given the space and functional constraints, customized battery designs are often the order of the day for more specialized medical devices. The case designs of these batteries, especially the button-type cells, are often specified by the device manufacturers themselves, employing special shapes (e.g., curves, semicircles, ovals) to maximize battery area and capacity while meeting critical space limitations within a particular device.

Fig. 2 – Cutaway of a button cell battery. (Credit: Emerson)

Whatever their shape or ultimate capacity, all medical device batteries rely on precision assembly processes. Ultrasonic metal welding technology is typically used. To bond the often thin and fragile foil electrodes, tabs and cases used in each battery, ultrasonic welding generates high-frequency (40–60 kHz), low-amplitude vibratory energy, then drives it through specialized acoustic tooling (a sonotrode or horn above, with a part-holding anvil below) that welds the fragile materials under controlled compression until bonding takes place (see Figure 1).

Unlike other welding processes that use high energy inputs, ultrasonic welding is clean; it generates no sparks and does not melt the fragile metals involved. Instead, the process creates solid-state, molecular-level bonds by generating frictional heat and compression between the metal parts. The acoustic tooling that accomplishes the ultrasonic welds is specified based on the battery application. Tooling for button cell batteries is relatively straightforward, since these typically employ a two-piece case, with the anode bonded to one side and the cathode to the other, with the center filled with an electrolyte (see Figure 2). But the production of devices that use cylindrical batteries often requires more specialized “long reach” tooling, a needle-like sonotrode that can reach down into the narrow cavity of a battery or product case, either to weld the “tabs” of a battery electrode to the base of the battery case or to join elements (bulbs, displays, circuits) circuitry within the device to battery power (see Figure 3).

Fig. 3 – Specialized long-reach tooling can reach down into the narrow cavity of a battery or product case, either to weld the “tabs” of a battery electrode to the base of the battery case or to join elements within the device to battery power. (Credit: Emerson)

Implantable cardiac devices such as pacemakers often demand compact battery designs, biocompatible materials, and long-lasting power supplies, since battery replacement is difficult or impossible. (Credit: Emerson)

In the coming years, companies such as Emerson will continue to evolve ultrasonic metal welding technologies to answer the needs of an ever-changing field of medical devices and the batteries that power them. Developing new assembly technologies will maximize the performance and precision of ultrasonic metal welding to satisfy the new design, size, and power requirements of advanced-performance medical devices.

Article Source: medicaldesignbriefs