At a Glance:

- Health and medical devices constitute a substantial waste stream and pose costly disposal challenges for manufacturers and health providers alike.

- Closed-loop recycling that could recover and reuse components and materials are a boon to the device manufacturer’s bottom line.

- A patented Branson plastic welding process, known as Simultaneous Through-Transmission Infrared (STTIr) laser welding, safely and nondestructively “unwelds” plastics commonly used in medical devices and wearables.

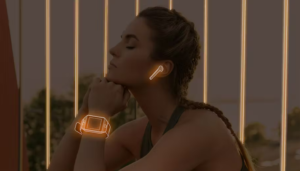

As global populations grow and age, demand is increasing for all sorts of medical devices, from wearable fitness and condition monitors to lightweight and easy-to-use therapeutic and drug delivery devices. Wearables include smart watches and fitness trackers, wearable blood pressure monitors and pulse oximeters, and a growing range of bio- and virus-detecting sensors. There are also testing and therapeutic products including blood-glucose testing devices and wearable continuous glucose monitors, epinephrine and insulin pens, and implantable insulin infusion-delivery devices.

Taken together, health and medical devices constitute a substantial waste stream and pose costly disposal challenges for manufacturers, health providers and consumers. Many of these devices are powered and contain valuable components that can be recovered and reused, such as batteries, specialized circuitry and logic, precious metals, plastics and more. Today, however, few such devices are subject to recovery, reuse or recycling.