Thanks to AI, Robots Are Aware of Their Surroundings

Robots started with limited capabilities. In the early decades, robots were mostly in automotive production. They lived in cages, tasked with one job, usually welding or painting. They required detailed and costly programming.

What a difference 60 years makes. Now robots can accomplish a wide range of tasks and they’re safe around human workers. They don’t require programming, and they can learn their environment and how best to navigate it. Plus, they’re way less expensive.

Juan Vega, CTO of Reliabotics, will explore the new world of robotics in his keynote presentation, A Robotics & Automation Industry Update, at IME East in New York on Wednesday, June 14 from 10:45 am to 11:30 am.

Robots have come a long way in the last couple of decades. In the last five years, we’ve seen particularly steep growth in robot technology. “Robotics and robots used to be positioned and closed in a fence. Now we’re seeing autonomous robots, and robot companies are bringing the cost down,” Vega told Design News. “Robots have become aware of their environment. You used to have to control their environment. Now we’re looking at machine learning and AI algorithms that teach the robot new tasks.”

Technology is giving robots a sense of their surroundings and how to move safely through it. “Robots are using cameras and RF sensors to get a better mapping of the environment,” said Vega. “The robots can determine the location of what needs to be picked up and they have an awareness of the obstacles. So they know where to pick it up and what obstacles to overcome.”

Intense Robot Programming Is Going Away

Robots no longer require costly programming. Workers with no software experience can teach a robot what it needs to do. “We’re seeing advances in materials handling, but the advances are also going into welding and surface finishing. You don’t have to have a programmer telling the robot how to go from point one to point two,” said Vega. “Before you had to use multiple programming languages such as BASIC or Fortran. Now, by using commercial technology, the robot can mimic what the human is doing, whether it’s polishing, sanding, or spraying. People are migrating away from many of those dangerous tasks.”

It’s only been in recent years that robots have developed into safe machines that can do complex tasks. “In the 2010s, we saw the arrival of the collaborative robot. We began to see app stores for robots. Robots went from very hard to program to easy configuration,” said Vega. “You could teach the robot by dragging it from one point to another. Now we’re getting away from that. You show the robot the target zone and the algorithm solves the motion. Not a lot the companies are doing that yet, but a lot of start-ups are developing it.”

Robots Are Entering New Sectors

Robots have taken over manufacturing and warehouses. “When you look at traditional manufacturing and indoor warehouses, you’re seeing an army of robots. They’re using a different technology. They’re mapping their environment like Amazon,” said Vega.

Robots started with limited capabilities. In the early decades, robots were mostly in automotive production. They lived in cages, tasked with one job, usually welding or painting. They required detailed and costly programming.

What a difference 60 years makes. Now robots can accomplish a wide range of tasks and they’re safe around human workers. They don’t require programming, and they can learn their environment and how best to navigate it. Plus, they’re way less expensive.

Juan Vega, CTO of Reliabotics, will explore the new world of robotics in his keynote presentation, A Robotics & Automation Industry Update, at IME East in New York on Wednesday, June 14 from 10:45 am to 11:30 am.

Robots have come a long way in the last couple of decades. In the last five years, we’ve seen particularly steep growth in robot technology. “Robotics and robots used to be positioned and closed in a fence. Now we’re seeing autonomous robots, and robot companies are bringing the cost down,” Vega told Design News. “Robots have become aware of their environment. You used to have to control their environment. Now we’re looking at machine learning and AI algorithms that teach the robot new tasks.”

Technology is giving robots a sense of their surroundings and how to move safely through it. “Robots are using cameras and RF sensors to get a better mapping of the environment,” said Vega. “The robots can determine the location of what needs to be picked up and they have an awareness of the obstacles. So they know where to pick it up and what obstacles to overcome.”

Intense Robot Programming Is Going Away

Robots no longer require costly programming. Workers with no software experience can teach a robot what it needs to do. “We’re seeing advances in materials handling, but the advances are also going into welding and surface finishing. You don’t have to have a programmer telling the robot how to go from point one to point two,” said Vega. “Before you had to use multiple programming languages such as BASIC or Fortran. Now, by using commercial technology, the robot can mimic what the human is doing, whether it’s polishing, sanding, or spraying. People are migrating away from many of those dangerous tasks.”

It’s only been in recent years that robots have developed into safe machines that can do complex tasks. “In the 2010s, we saw the arrival of the collaborative robot. We began to see app stores for robots. Robots went from very hard to program to easy configuration,” said Vega. “You could teach the robot by dragging it from one point to another. Now we’re getting away from that. You show the robot the target zone and the algorithm solves the motion. Not a lot the companies are doing that yet, but a lot of start-ups are developing it.”

Robots Are Entering New Sectors

Robots have taken over manufacturing and warehouses. “When you look at traditional manufacturing and indoor warehouses, you’re seeing an army of robots. They’re using a different technology. They’re mapping their environment like Amazon,” said Vega.

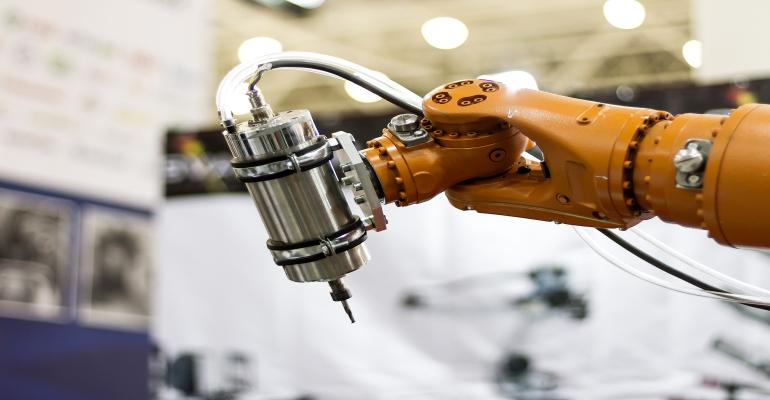

A robot is drilling into the side of a subway wall in New York City. This is an example of a robot at work in construction.

Now, robots are going beyond the traditional sectors to industries that are new to robots. “Kuka is doing cool things with MRIs in medical. They have a large robot moving ultrasound equipment. Robotic surgery is growing by the day,” said Vega. “We’re seeing robots in construction. The biggest issue there is the non-static environment. So you use different techniques to make the robot aware, lidar or 3D vision.”

Article Source:MDDI