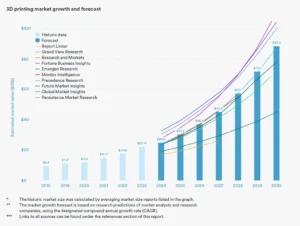

Protolabs 3D Printing Report Shows Growth Exceeding $28B

Protolabs’ 3D Printing Trend Report offers a snapshot of the additive manufacturing industry, showing the trends that are driving 3D printing’s growth. Through key market data and a survey of the global engineering community, Protolabs’ 2024 report depicts a healthy level of confidence in the 3D printing market. The result points to potential for further growth in production-level manufacturing as the technology moves beyond prototyping. In addition, micro and large-format applications continue to expand.

Key findings include:

-

3D printing market growing 10.5% faster than predicted

-

2024 market size estimated at $28.1 billion

-

Market to reach $57.1 billion by the end of 2028

-

More than 70% of businesses printed more parts in 2023 than in 2022

-

A full 77% reported the medical sector has most potential for impact

3D printing has evolved to occupy an established place in manufacturing today. As it has become a more widely applied industrial manufacturing process, the industry is coming of age. A large network of specialized companies providing support and solutions for a range of production processes has emerged.

From design software through automated production solutions to enhanced post-processing methods, this budding ecosystem signals that production-level 3D printing is used by ever-growing numbers of businesses. The wider availability of specialized solutions in turn increases the uptake of production level 3D printing.

Graph courtesy of Protolabs.

3D Printing’s Growth in Production

The data shows that 3D printing is steadily moving beyond prototyping towards production applications. Protolabs’ annual report reveals a steady growth in production-run volumes: Respondents who said they printed more than 10 parts rose from 36% in 2020, to 49% in 2021 and to 76% in 2023.

The mindset around additive and production is slowly changing as well. “Production volume and scale” was named by 45% of survey respondents as a factor for choosing other manufacturing methods over 3D printing—down from 47% in the previous year.

Innovative Materials on the Rise

Moving forward, the report found the expansion of available materials and related technologies will play a vital role in shaping future use cases. For example, nearly a third of respondents reported multi-material printing will have the biggest impact on 3D printing growth, second only to hybrid manufacturing, which combines additive technology with traditional services.

Industry experts agree that highly specialized materials designed for 3D printing applications are coming to market, providing even more scope for innovation. “Companies are designing blends actually tailored for 3D printing,” Adam Hecht from 3DP design studio DIVE said in a statement. “They’re creating a lot of materials that are geared for very specific applications within 3D printing, whether that’s conventional thermoplastics that have been re-engineered for 3D printing, or resins that aren’t just for prototyping, but for very specialized, high-temperature, high-elasticity types of applications.”

Where Is AI Taking the Technology?

As the excitement of AI permeates almost every sector, 3D printing is no exception. Protolabs’ report reveals the big promise of an AI-disrupted industry has yet to be fully realized. However, smart printers are getting smarter and improving the user experience. Nearly a third of respondents identified automated print tuning as the top impact from AI, followed by non-planar FDM printing through improved slicer software (25%). Design for additive manufacturing will also benefit from AI innovations – think topology optimization, multiphysics process simulation, and AI-generated CAD.

For more about the status of additive manufacturing—broken down by industry and region—and where 3D printing is heading next, download the full report.

Article Source: MDDI