3D Printing in Dentistry: Now and the Future

3D printing has disrupted traditional manufacturing in diverse industries including aerospace, defense, art, and design. Medical applications, including dentistry, are now leveraging existing 3D imaging as inputs to enable 3D printing.

This article discusses applications leveraging both existing dental 3D printing technologies and future applications including productization in both simple and complex workflows, with more currently being commercialized.

Dental 3D Printing Process

Prosthetic dentistry, which provides patients with replacements for damaged tissue such as crowns, bridges, and implants, is the main focus of 3D printing applications. This is due to the automatability of these processes. Hard tissues are fixed in space relative to themselves (dental archways, over short timespans with no applied forces), and imaging and planning are already a part of the process for tissue repair or replacement.

Planning begins with imaging techniques like intraoral scanning and cone beam computed tomography (CT), which are already prevalent in the industry. CAD/CAM software is also common, with a long history of use in dental labs and in practices with benchtop systems. CAD (Computer-aided design/drafting) involves drawing and creating models in 2D, 3D, or both. CAM (computer-aided manufacturing) is a process where these drawings and models can be converted into machining language and passed to an automated fabrication system (like Dentsply Sirona’s CEREC), which will then create components out of raw material.

These are all relatively common in dentistry, but growth areas that can leverage the existing infrastructure include novel materials and fabrication methods for prosthetics surgery.

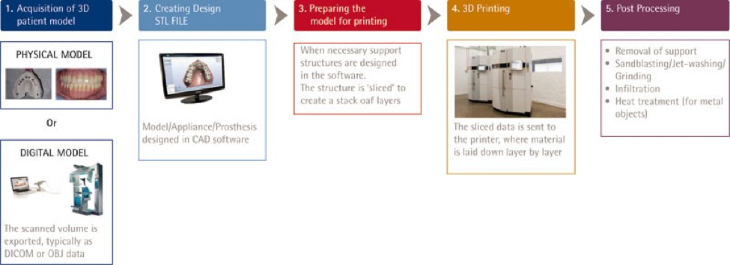

Dental 3D printing process flow chart. Image courtesy of British Dental Journal.

The first step is to derive a patient model. The modern and most frequent method uses a volumetric scanning device, which captures an anatomical surface of the patient’s key anatomy into a file structure, generally DICOM, OBJ, or STL (3D files).

3Shape’s TRIOS 3, a leading intraoral dental scanner. Image courtesy of 3Shape.

The patient scan is then transferred to a CAD tool, where the 3D anatomy can be manipulated and used for the design of the device (e.g., surgical guide or prosthetic crown).

The next step is designing the printed component, by:

providing necessary support for the print in CAD (e.g., support columns)

laying a support foundation for the print

setting resolution of the print (such as layer thickness)

These steps can increase/decrease both time and quality of a print in an inverse relationship.

Finally, 3D printing can take place. After loading the system with applicable files and a material option, the 3D printer then builds the component(s) layer by layer until complete.

The component(s) is then post-processed, including support removal, surface finishing (polishing, deburring, blasting, etc.), sealing, and heat treatment (if applicable). Control of these steps is critical to create a final component ready for use in patients, including implications of biocompatibility with target contact tissues.

Drill Guides—Dental Implants

One 3D printer and printing materials vendor offers 3D printed surgical guides, which are designed as a 3D print overlay on the scanned profile of a patient’s teeth. An insert can then be placed, which helps constrain the drill in place, limiting planar movement relative to the draw axis of a planned implant. The drill can then be guided and constrained to cut tissue until bottoming out on the guide, providing a prepared hole for installation of an implant base-screw. Documentation for accuracy and processing is also available for anyone hoping to bring the process in-house, as this system is intended to be integrated into existing dental surgery practices. This involves, in chronological order: printing, buffing/smoothing, metallic drill guide install, sterilization/cleaning/disinfecting, and curing. When cured and ready for use, the material is certified as biocompatible.

Drill guide for dental implant pilot holes. Image courtesy of Formlabs.

Summary

3D printing in dentistry is both established and promising. It leverages existing technology already deployed in the field to provide new solutions to established procedures. Future blogs will provide details on more ground-breaking applications in dentistry, such as:

Planning tools for prosthodontics, orthodontics, and surgery

Clear aligners

Implant and prosthetic restorations

Article source: Medical Product Sourcing