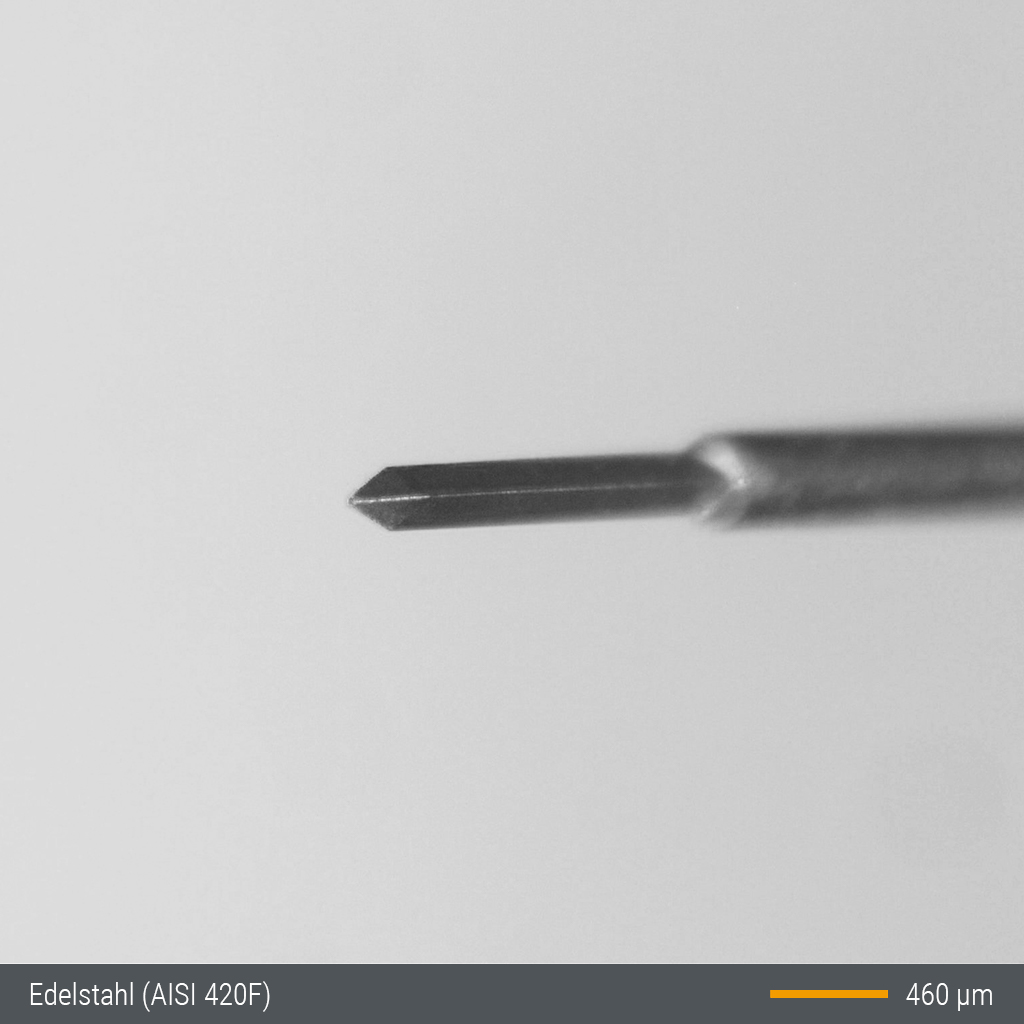

Micro-trimmers for minimally invasive procedures

Laser cutting

The GFH GmbH is one of the global leaders and technology pioneer in designing and engineering of high precision laser micro machines with ultrafast lasers.

One of the focus areas lays within the continuous development of the “tool” called laser. Nowadays, the laser technology is already applied for different types of processing, with lowest tolerance and no deterioration, such as: micro cutting, laser turning, laser drilling, micro structuring and micro engraving.

As a result, the laser technology of GFH does not only improve the productivity of serial production but also lays the foundation for innovative production methods and future production demands.

In addition we offer a professional job shop where our clients needs are met. This production takes place in our company building with our own inhouse manufactured laser micro machines.

On behalf of a company based in the medical industry, GFH GmbH uses its in-house laser systems to manufacture micro-three-knife trimmers for minimally invasive medical interventions.

Through laser micro cutting, often referred to as precision cutting, GFH uses its high-precision investment technology to cut ferrous and non-ferrous metals as well as non-metallic materials for example ceramics up to a thickness of 1 mm. This includes the sophisticated micro-three-knife trimmers, which are used every day in the medical sector.

The advantages of laser cutting are the ability to flexible adjustment of the cutting angle, and thus to change the shape of the cutting edge quickly and easily, especially when machining the micro-three-knife trimmer.

By means of laser technology, it is also possible to machine very fine geometries without the influence of mechanical forces on the component, which prevents tool wear and ensures the consistent quality of the final product. Further advantages of this method are the replacement of individual working steps (eroding, grinding, etc.) by the innovative laser technology, the machining of flexible cutting contours (3D), as well as the possibility of automation – especially when processing the micro-three-knife trimmer. In addition, the time required for micro-cutting significantly undercuts the duration of a comparable processing method as grinding. In addition to a wide range of adjustment options for the trepanning and focusing optics for kerf diameter and cutting angle, it also allows uncomplicated adaptation to the respective application and thus economic production of even low piece counts.

Laser cutting offers advantages such as fast processing time, accuracy and a very high and consistent quality.