The choice between custom and off-the-shelf electromagnetic sensors in medical devices can have an impact on product development and market performance.

As electromagnetic (EM) sensors become core components in next-generation wearables, implants, and neurotech devices, product designers face a deceptively simple yet critical choice early in development: should they rely on off-the-shelf components or pursue a custom solution?

The decision can make or break a product, shaping not only sensor performance, but also manufacturability, development timelines, regulatory approval, competitive positioning, and clinical outcomes.

Yet too often designers and OEMs underestimate this pivotal decision, often defaulting to off-the-shelf EM sensors without fully considering whether a custom solution would better align with their needs and goals. Here’s a detailed look into how this hidden decision truly defines product success.

The myth of off-the-shelf efficiency

It’s easy to assume that off-the-shelf EM sensors are faster, cheaper, and “good enough” for early prototypes. In some cases, they do offer advantages such as lower initial cost, immediate availability, and rapid turnaround for proof-of-concept builds.

However, as a device moves from prototype to integration, scaling, and regulatory review, the limitations of off-the-shelf EM sensors begin to reveal themselves—increasing risk and introducing unexpected costs:

-

Compromised form factor. Off-the-shelf EM sensors might not align with enclosures, working channels, flex-PCBs, or surgical requirements.

-

Signal interference. This could be caused by poor sensor sensitivity, packaging, or proximity to other components.

-

Unexpected failure modes. Failures often surface during sterilization or wireless operation.

-

Regulatory delays. Off-the-shelf sensors typically aren’t pre-validated for regulatory approvals such as FDA clearance or CE marking.

-

Supply chain volatility. The availability of off-the-shelf sensors might change, making it difficult or impossible to scale without design modifications.

-

Limited supplier support. Catalog vendors typically do not provide deep design support or customization assistance.

These limitations should give OEMs and engineers pause when considering off-the-shelf EM sensors. The last thing you want is to invest in engineering your device, only to encounter late-stage issues that force costly redesigns, delay market entry, or risk product success.

How custom electromagnetic sensors reduce risk, accelerate development, & lower costs

Custom EM sensors—when designed in close collaboration with experienced manufacturing partners— can significantly reduce risk, streamline development, and lower lifecycle costs for next-generation medical and neurotech devices.

Strategic design

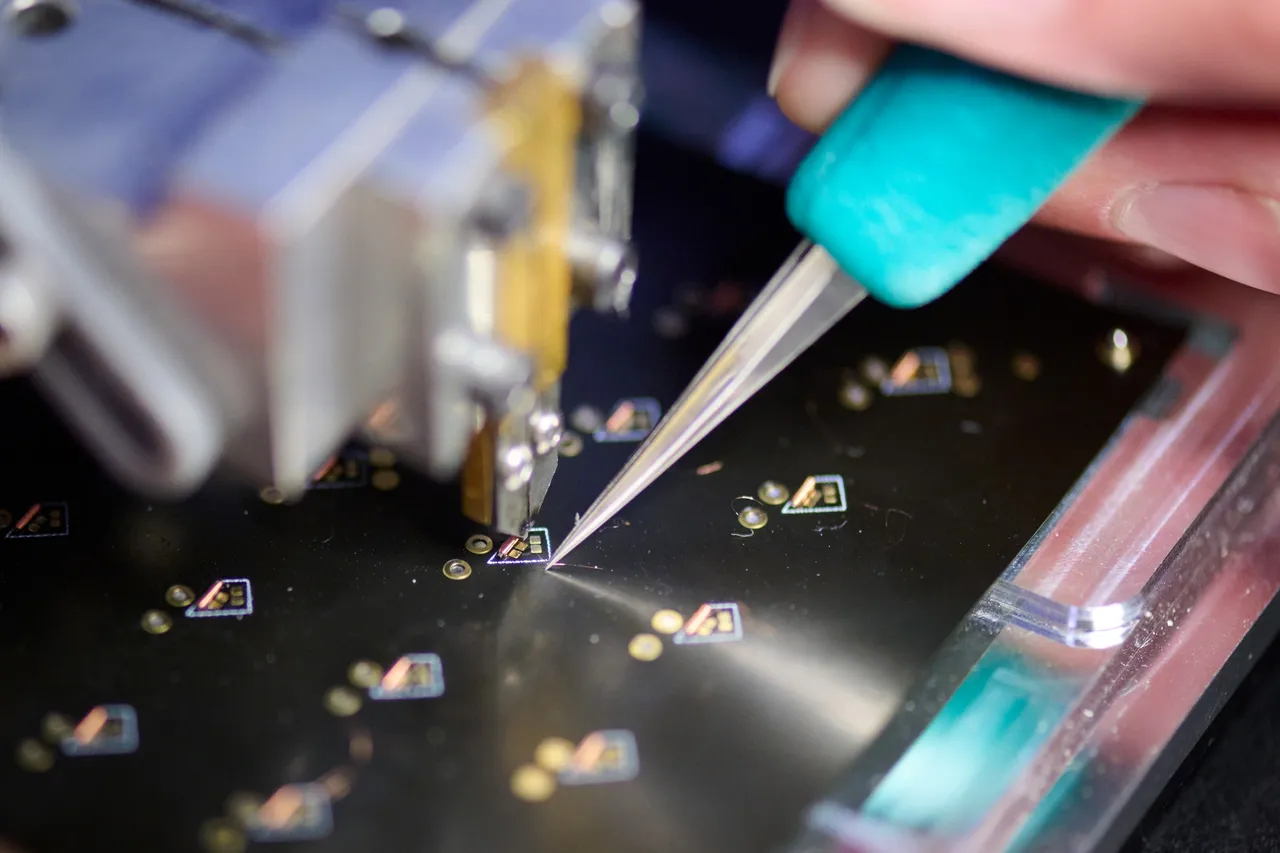

Custom EM sensors match geometry, signal sensitivity, material selection, shielding, and winding specifications precisely to your device. That means core geometry shape, size, number of sensors, placement, and form factors can all be custom-designed to fit tight space constraints, integrate with surrounding components, and optimize overall functionality. For example, custom EM sensors can be designed to integrate seamlessly with PCBs—a common challenge with off-the-shelf sensors.

This advanced level of precision has an enormous impact on performance. Even minor coil misalignments at scale can degrade EM signal performance. Custom approaches achieve tolerances that off-the-shelf sensors cannot match.

Power management strengthens the case for customized solutions that can reliably transmit wireless data within your power budget, which is critical for implanted devices that must operate for years without recharging or removal.

One-size-fits-all solutions do not cater to the unique complexities of exact use cases. Though catalog parts appear cheaper upfront, custom sensors often result in a lower total cost of ownership when considering long-term performance, risk, and lifecycle costs. It’s important to choose the right option to meet performance demands while maintaining overall budget and manufacturability.

Design for manufacturability (DFM)

Off-the-shelf sensors often introduce challenges—whether compromised form factors or signal interference—and each must be solved at scale. That can quickly become expensive if you must modify other components to accommodate the sensor.

Many OEMs and engineers engage contract development and manufacturing organizations (CDMOs) late in the design process, when it’s difficult and costly to pivot. However, leveraging CDMOs that follow DFM principles allows you to design custom sensors that are:

-

Cost-effective to produce

-

Scalable for high-volume manufacturing

-

Perfect form factor fits

-

Reliable and marketable

The result? Lower production costs, less risk, and accelerated time to market.

Biocompatibility & MRI safety

Biocompatibility is crucial for performance and safety. Some implantable devices must reliably operate for years without needing to be recharged or replaced. In addition, many sensors must be designed for MRI safety.

While some off-the-shelf EM sensors claim MRI safety, only custom sensors can be optimized for specific use cases, which can reduce trial and error while expediting regulatory approval.

Signal validation that meets clinical gold standards

High-fidelity wireless signals are paramount in today’s applications—especially when sensors provide surgical insights or implanted devices must transmit data through tissue. However, off-the-shelf sensors might not deliver the signal integrity needed to inspire confidence in your device.

For example, Intricon was approached by an OEM whose product was failing in the field due to magnetic interference with their catalog EM sensor. Unable to find a catalog solution, they partnered with Intricon, and we delivered a custom prototype that mitigated interference—in just two days. A true DFM CDMO, we also identified ways to cut costs in half.

The bottom line? Custom sensors allow you to implement application-specific EM sensor solutions to ensure reliable and accurate operation, even in electrically noisy environments such as surgical suites. Moreover, custom solutions can be developed quickly and cost effectively.

Temperature & humidity

Temperature, humidity, and altitude can all impact EM sensor performance, but off-the-shelf sensors rarely account for these variables. Custom sensors, on the other hand, can be engineered to reliably perform in real-world environmental conditions, not just lab climates.

For example, a device that performed perfectly in clean lab environments began failing data validation once tested in a surgical suite. The late discovery forced a complete redesign that delayed time to market, which could have been prevented if the OEM had partnered with a sensor expert early in the design process.

A strategic choice, not just a sourcing decision

Ultimately, choosing between a custom or off-the-shelf EM sensor isn’t simply about sourcing a component—it’s about alignment. It’s a strategic decision that impacts the entire product lifecycle, from R&D through clinical use to long-term market performance.

Sensor selection directly influences device integration, usability, regulatory approval, competitive positioning, and patient outcomes. The decision shouldn’t be made in isolation, but aligned across engineering, clinical, regulatory, and business development teams to ensure the strategy supports overall product goals.

The wrong sensor choice can introduce hidden risks that surface late in the process, leading to costly requalifications and redesigns, development delays, and missed opportunities. In contrast, selecting the right sensor strategy early helps balance performance, cost, and manufacturability—delivering exactly what the application requires without unnecessary complexity or cost.

Custom sensors simplify integration, reduce risk, streamline regulatory approval, and lend a competitive advantage—all while accelerating time to market. For product designers navigating the high-stakes world of connected medical devices, custom sensors might just be the quickest path to success.

source:mddionline

https://www.mddionline.com/components/custom-vs-off-the-shelf-em-sensors-a-strategic-choice-for-medical-device-success

This article is for knowledge dissemination only. If it involves infringement, please contact us for deletion.