Control valves for home care medical devices must become more efficient

Device OEMs can meet fast-growing demand by combining the flexibility of new and proven flow-control products with supplier expertise.

By Paul Gant, ASCO Analytical and Medical at Emerson

A portable oxygen concentrator manifold solution with a credit card for scale [Photo courtesy of Emerson]

The trend to design capable medical devices for home and mobile care is not new, and most medical device manufacturers have made robust investments in this growing market. Portability and ease of use are key areas of development, and component and control solutions manufacturers must innovate to keep up with demand.

Medical devices such as oxygen concentrators, compression therapy devices, therapeutic support surfaces, and dialysis equipment utilize solenoid valves to automate control of the equipment. These devices must meet the requirements of the governing authorities — including the FDA and European Union Medical Device Regulation (MDR) — and accommodate the shift from a traditional setting, such as a hospital, to a step-down care facility or home setting.

However, each of the devices listed above has unique control challenges that must be overcome to better meet the needs of these new environments. The control valve solution must be more compact, highly durable, and easy to use and maintain, and it must also help the medical device improve the patient’s quality of life.

Solenoid valves and portability: Higher performance in a smaller, lighter package

Miniature solenoid valves used for deep vein thrombosis devices [Photo courtesy of Emerson]

Solenoid-operated valves are commonly used in the controls of medical devices because they offer value and reliability while providing excellent functionality. Valves control the direction of the flow of air or various gases and also control gas pressures. The gas pressure in most medical devices is typically lower than industrial applications — often below 2 bar (30 psig) — so a typical valve used in a medical device may need to be far more sensitive in controlling small gradations in flow and pressure than valves used in industrial or other segments.

A growing number of solenoid valves are either designed specifically for or adapted to home-care or other portable devices. In these applications, the emphasis is on compact, lightweight valves that offer high rates of gas flow with minimal power usage. Some valve designs allow for use of a power reduction circuit, which serves to reduce the overall power level required to operate the valve. Since many portable devices must be powered by battery, innovations like the power-reduction circuit become quite important.

Among the most popular solenoid valves in medical devices are those that combine a small size and lightweight platform with the ability to easily customize the valve’s body so that it can precisely regulate flows in a variety of patterns while fitting into the envelope of the engineer’s overall device design.

Recently, these valves have been adapted to offer similar performance in a reduced footprint. Such adaptation is driven by the need of valve suppliers to give the design engineer an additional tool to enable optimal treatment, tailored to the patient’s condition, along with the key characteristics needed to perform in varied care environments, whether critical care, home care or something in between.

Valve customization

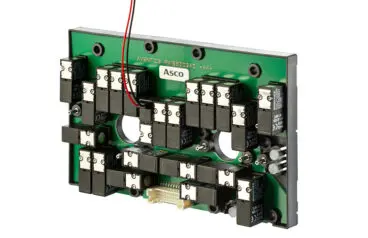

Manifolded valves in a single assembly, including efficient wiring, used in peritoneal dialysis machine [Photo courtesy of Emerson]

The OEM design engineer faces multiple challenges when contemplating a medical device. For a device that will be used in a home-care setting, design engineers must also grapple with size, weight, power, and ease or simplicity of use.

Solenoid and other miniature valves offer several technical advantages for home-care and portable medical devices. Valve suppliers are well versed in the design of miniature solenoid and similar control-valve solutions and are fully capable of navigating the regulatory requirements associated with medical device applications worldwide.

These capabilities combine to assist the medical device design engineer in configuration control while accelerating the design and development cycle to get the product into production and use as quickly as possible.

What to look for in valve suppliers

ASCO designed its Series 090 three-way miniature solenoid valve for lighter, more space-efficient solutions for gas control in oxygen therapy, compression therapy and gas analyzer devices [Photo courtesy of Emerson]

It is important to seek out a valve supplier that is adept at combining solenoid valve functions with sensor feedback and building the electronic interfaces needed to automate (and simplify) valve and device operation.

A capable supplier should also have the ability to design, customize, or deliver complete subassemblies to the medical device OEM that are fully assembled, tested, and ready to install and use in the medical device.

Many suppliers of miniature gas and liquid control valves have standard product portfolios. However, given the unique design challenges faced by medical device manufacturers — portability, energy efficiency, scalability, and use of digital data — it can be beneficial to work with suppliers that develop customized solenoid valve configurations that can meet unique requirements. This includes working with suppliers that:

- have engineering resources available to quickly adapt standard products to custom configurations,

- are experienced in integrating electronics into miniature control solutions and in integrating solenoid valves into complete subassemblies,

- and offer design and production quality systems that align with medical device regulations, including the latest FDA and MDR standards, to assure the OEM that its devices represent the best possible solutions available.

Conclusion

The ASCO Series RB miniature solenoid valve [Photo courtesy of Emerson]

While the miniature solenoid valves might be “simple” in their core technology, rapid evolution of the medical device market is driving constant innovations in the ways that these valves must perform in controlling the flow, direction, and pressure of gases and fluids.

By combining the flexibility of new and proven flow-control products with the engineering expertise offered by the valve supplier, medical device OEMs can offer optimal solutions, from valves to complete subassemblies, to meet the needs of a fast-changing, fast-growing global market.

Paul Gant is the senior business development manager, ASCO Analytical and Medical at Emerson. [Photo courtesy of Emerson]

Paul Gant is the senior business development manager, ASCO Analytical and Medical at Emerson. Gant has extensive experience with the use of miniature solenoid valves and pressure/control solutions. He holds a BS in business management from California Coast University and an MBA in international business from Liberty University.

How to submit a contribution to MDO

The opinions expressed in this blog post are the author’s only and do not necessarily reflect those of Medical Design & Outsourcing or its employees.