Stratasys and CollPlant Partner to Bioprint Breast Implants

When it comes to 3D printing in healthcare, a long-term goal has been to print human tissue that can potentially be grown into new organs. While 3D printing a new heart for a patient isn’t currently a reality, a growing number of companies are developing their own methods of printing tissue that can be used in implants, and, they hope, eventually organs.

Animal study demonstrates tissue regeneration

In January 2023, Israel-based medical company CollPlant Biotechnologies announced that it had successfully completed a large-animal study for its 3D bioprinted regenerative breast implants. After three months, the study demonstrated progressive stages of tissue regeneration, shown by the formation of maturing connective tissue and neovascular networks within the implants. No adverse effects were reported, in contrast to traditional silicone implants, which carry risks of complications such as immune response and rejection.

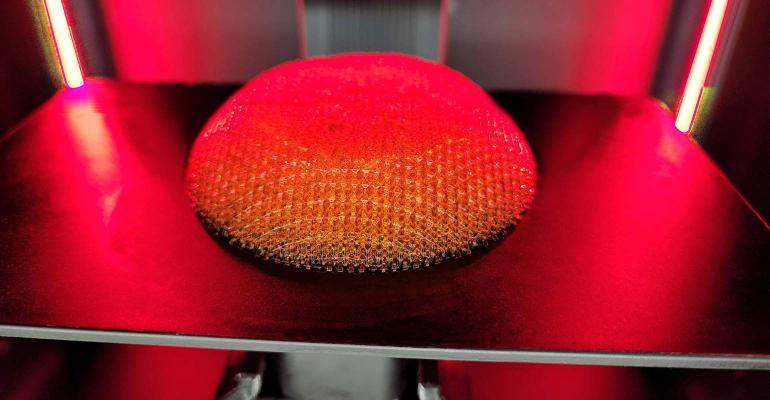

This week, CollPlant signed a joint development and commercialization agreement with Stratasys to further develop bioprinting technology. The partnership will combine CollPlant’s rhCollagen-based bio-inks with Stratasys’ P3 technology-based bioprinter. P3, which stands for Programmable PhotoPolymerization, is an evolution of digital light processing (DLP) technology aimed at the mass production of functional end-use parts.

The new bioprinter, used with CollPlant’s bio-inks, will be at the center of the partnership’s first project, which focuses on the development of industrial-scale production of CollPlant’s regenerative breast implants.

Bioprinting overcomes challenges of existing breast procedures

“Stratasys is leading in additive manufacturing and we are excited to collaborate with them on this transformative initiative,” said CollPlant CEO Yehiel Tal. “P3 technology allows printing with high resolution and process control, and we believe that the combined, pioneering technologies of both companies will streamline the development and production process so that we have the most efficient means to produce our regenerative breast implants and other potential tissues and organs. We believe that our rhCollagen-based regenerative implant has the potential to overcome the challenges of existing breast procedures that use silicone or autologous fat tissue transfer.”

Breast reconstruction and augmentation is the second most common plastic surgery procedure performed worldwide today. Based on the positive results of its first large-animal study, CollPlant plans to initiate a follow-up large-animal study in the second half of 2023 using commercial-size implants to support future human studies and product commercialization.

Aim is to accelerate industrial-scale bioprinting

“Through this partnership with CollPlant, we have an important opportunity to transform healthcare with bioprinting to improve the lives of patients undergoing breast augmentation or reconstruction procedures,” said Stratasys CEO Dr. Yoav Zeif. “This agreement is well-aligned with our strategy to deliver complete solutions for high-growth industry applications with our ecosystem of partners, and the production scale and precision 3D-printing capabilities of Stratasys’ P3 Programmable Photopolymerization technology are a particularly strong fit for bioprinting applications. We believe that partnering with CollPlant will enable us to accelerate the industrialization of bioprinting for regenerative medicine, and we look forward to collaborating toward the successful commercialization of CollPlant’s novel regenerative breast implants and beyond.”

Each company will cross-promote the other’s bioprinting products, with Stratasys’ bioprinter being offered together with CollPlant’s bio-inks, and vice versa. The companies also state that their technology can be used in the future for the development and production of additional human tissues and organs.

Medical Source:MDDI