Laser Solutions for Device Cutting from Tubes and Flat Stock

Two medical device manufacturing companies share their experiences with specialty laser-cutting machines…….

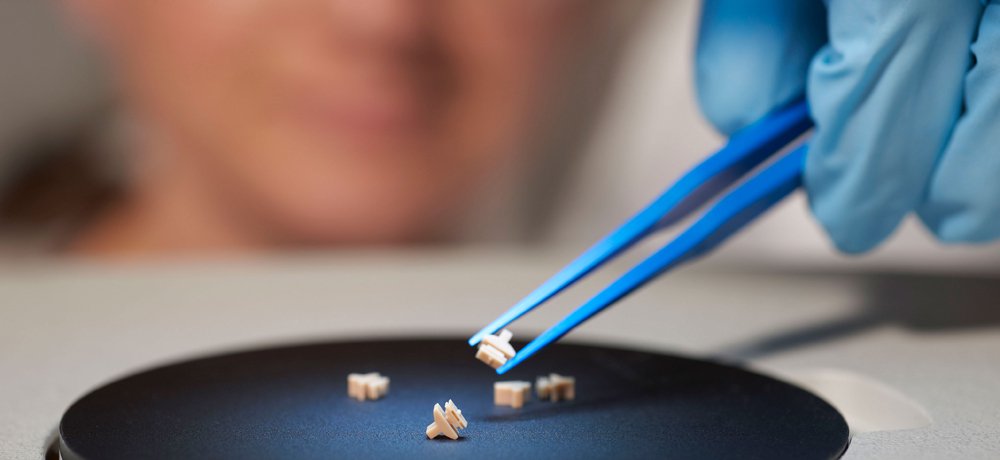

The Benefits of Embedding Marker Bands vs. Swaging

Advancements have enabled marker bands to be applied more safely and consistently.

Advanced Technology for Plastics Staking and Swaging

A new “pulse staking” process could enable medical device designers to use more diverse and complex designs and a wider range of plastics than existing heated-tip and ultrasonic technology allow.

Finding the perfect balance with tubing, catheters and stents

When can you stretch or adapt extrusion capacity and when should you retool? Ernie Preiato, vice president of extrusion, and Dave Czarnik, R&D/lab manager of extrusion, both from Conair explains.

Thinking small: Accumold discusses risk mitigation in micro molding

Spoke to Aaron Johnson, VP of marketing and customer strategy at Accumold, to find out more about risk mitigation in micro molding.

Advancing Medical Device Manufacturing with Factory of the Future Technology

Enhance productivity, improve quality control, and promote continuous improvement by identifying the right solutions and partnering with the right supplier.

How to improve ultrasonic weld quality

An electromechanical actuation system that delivers downforce with greater precision and responsiveness throughout the ultrasonic welding process can improve the weld and reduce waste.

Is Metal Additive Manufacturing for You?

Consider the total cost per part from all pre-printing, printing, and post-printing processes as well as other cost drivers.

The Science of Multi-Layer Extruded Tubing and Medical Devices Incorporating Such Tubing

Multi-layer extrusion technology is a process in which two or more polymers are extruded and simultaneously joined in a co-extrusion die head to form tubing with multiple layers.

Making Connections to Accelerate Medical Device Assembly

As medical devices become smaller and more complex, designers and manufacturers are utilizing new and more sophisticated components to incorporate into their device designs. Patients want smaller, more portable devices while providers want more functional and better performing alternatives. This includes items such as IV tubes and bags, drainage catheters, dialysis machine tubing, and a host of other products using tubing and hoses.